Did you know that the global wine storage market is projected to reach $2.7 billion by 2027?

As wine collections become increasingly valuable investments, proper commercial storage has never been more crucial. Whether you’re a restaurant owner, wine merchant, or storage facility operator, understanding the complexities of commercial wine storage is essential for preserving both quality and value.

In this comprehensive guide, we’ll explore everything you need to know about commercial wine storage solutions, from temperature control systems to inventory management.

Welcome to Didi Somm and Cheers!

Important Notice: The information in this article is for general and public information purposes only. It solely reflects Didi Somm’s or his Staff’s opinion, and no responsibility can be assumed for errors or omissions in the service’s contents. For details, please check the Disclaimer at the bottom of the homepage.

Key Takeaways

- Temperature and humidity control are critical factors in commercial wine storage

- Professional storage facilities require specific design considerations and equipment

- Proper inventory management systems enhance operational efficiency

- Regular maintenance and monitoring ensure optimal storage conditions

- Compliance with local regulations is essential for commercial operations

Understanding Commercial Wine Storage Requirements

Let me tell you, getting the environmental conditions right in a commercial wine storage facility is no joke!

Temperature

After 15 years in this industry, I’ve learned that temperature control is absolutely critical – and I found this out the hard way when a faulty sensor once cost me a whole collection of premium Bordeaux. The sweet spot? You’ll want to maintain a consistent temperature between 55-57°F (13-14°C), with minimal fluctuations. Trust me, even a 5-degree swing can impact wine aging.

Humidity

Humidity is another beast altogether. I remember installing my first commercial-grade humidity monitoring system – what a game-changer! You’re aiming for that perfect 60-70% range. Too low, and those corks will dry out faster than a raisin in the sun; too high, and you’re inviting mold to the party. I now use digital hygrometers with remote monitoring capabilities in every storage zone.

Light Exposure

Light exposure? That’s your wine’s worst enemy after temperature fluctuations. UV rays can trigger chemical reactions that wreck your inventory’s flavor profile. I’ve installed LED lighting with motion sensors throughout my facility – they produce minimal heat and automatically shut off when no one’s around. Pretty nifty, right?

Vibration

One aspect folks often overlook is vibration control. Think about it – would you want your precious wines doing the cha-cha on the shelf? I learned to install specialized rubber mats under racking systems and keep storage areas far from any mechanical equipment. Even minor vibrations from HVAC systems can disturb wine sediment over time.

Ventilation

Speaking of HVAC, proper ventilation is crucial for maintaining air quality. I use a combination of activated carbon filters and air exchange systems to prevent any musty odors from developing. Bad air circulation can lead to that dreaded “cellar taste” that nobody wants in their wine. Plus, good ventilation helps maintain consistent temperature and humidity levels throughout the space.

Pro Tip: Install redundant monitoring systems for all these environmental factors. When you’re storing millions of dollars worth of wine, you can’t afford to rely on a single point of failure. I’ve set up alerts that ping my phone if any parameters drift outside acceptable ranges – it’s saved my bacon more times than I can count!

Designing Commercial Wine Storage Facilities

You know what’s fascinating about designing wine storage facilities? It’s like putting together a giant puzzle where every piece needs to be climate-controlled!

Space Planning

I’ve spent years perfecting the art of space planning, and let me tell you, the devil’s in the details. My first facility taught me that you need at least 30% more space than you initially plan for – wine collections have this amazing way of growing beyond expectations.

Storage Solutions / Layouts

I remember staying up late one night, sketching out different racking configurations on napkins (yes, really!). After trying various layouts, I discovered that combining different storage solutions – bulk storage for cases, individual bottle racks, and high-value wine displays – creates the perfect balance of efficiency and accessibility. Now, I use 3D modeling software, but those napkin sketches taught me the fundamentals! To see actual commercial wine storage/racking solutions, please check Wine Racks America or Vinotemp websites.

Loading Zone

The loading zone was my biggest headache initially. Picture this: a delivery truck arrives with $100,000 worth of wine, and you’re scrambling to maintain temperature control while unloading. Rookie mistake! These days, I insist on climate-controlled loading docks with airlocks, specialized hydraulic lifts, and extra-wide corridors. Makes life so much easier!

Security

Security? Well, that’s where I might go a bit overboard – but hey, when you’re protecting liquid gold, can you blame me? I’ve implemented everything from biometric access controls to vibration sensors in the walls. One time, our system detected unusual movement at 3 AM – turned out to be a curious raccoon, but better safe than sorry!

Emergency Backup Systems

The real game-changer was installing emergency backup systems. After a power outage nearly ruined a client’s vintage collection, I now have triple redundancy on everything. Multiple generators, backup cooling systems, and even portable cooling units as a last resort. Some people think I’m paranoid, but in this business, you can’t be too careful.

Temperature Control Systems and Equipment

Getting technical about temperature control might sound boring, but it’s honestly the heart and soul of wine storage.

Commercial HVAC System

I’ll never forget my first major investment in a commercial HVAC system – talk about sticker shock! But here’s the thing: when you’re safeguarding millions in wine inventory, you need industrial-grade equipment that can maintain rock-solid temperature stability.

Multiple Small- vs. One large Unit

My journey with cooling units has been quite the learning experience. After testing various systems, I’ve found that multiple smaller units offer better redundancy than one large system. They’re easier to maintain, and if one goes down, you’re not completely out of luck. Plus, they allow for more precise temperature zoning, which is crucial when you’re storing different types of wine.

Temperature Zoning

Speaking of zoning – it’s like conducting an orchestra where every section needs to play at exactly the right temperature. I’ve created separate zones for red wines, white wines, and champagnes, each with their own dedicated cooling units and monitoring systems. Even installed special low-velocity air handlers to prevent any direct drafts on the bottles.

Monitoring Systems

The monitoring system I use now is like something out of a sci-fi movie. Wireless sensors throughout the facility feed real-time data to a central dashboard, with automated alerts if anything goes even slightly out of whack. I can check temperatures from my phone at 3 AM if I want to (and yes, I’ve definitely done that more than once!).

Backup Power

Backup power? That’s where I learned my lesson the hard way. A 36-hour power outage during a summer heatwave taught me the value of redundancy. Now, I’ve got automatic transfer switches connected to multiple backup generators, plus UPS systems for all monitoring equipment. It might seem like overkill until that one time when you really need it!

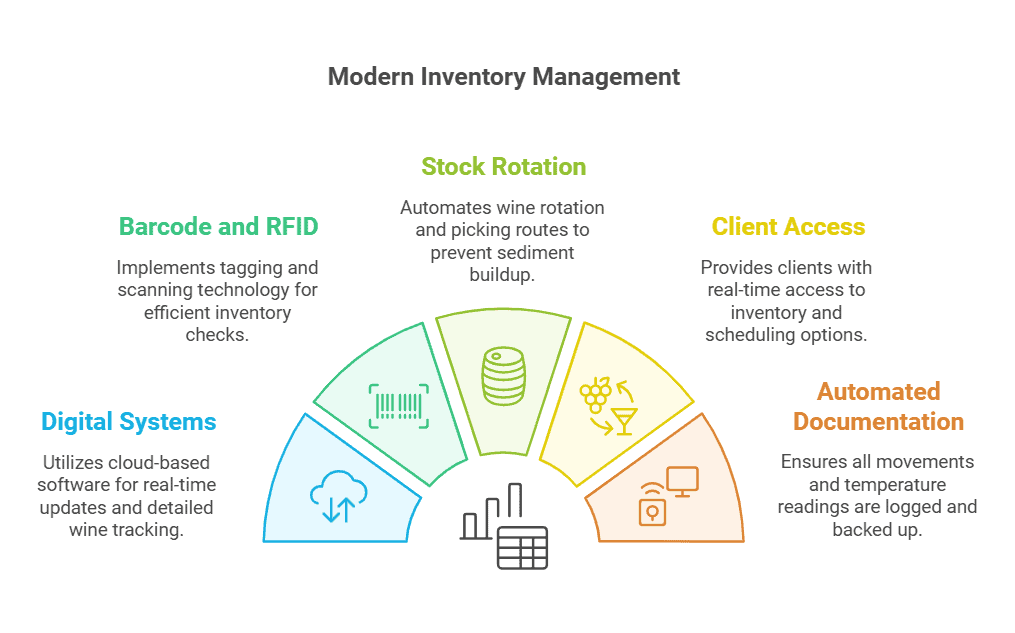

Inventory Management and Organization

Boy, has inventory management come a long way since the days of clipboard checklists! I remember spending countless hours manually counting bottles and updating spreadsheets. These days, I’m all about digital systems – they’ve literally transformed how we track and manage wine collections. We’re talking cloud-based inventory software that updates in real time, complete with photos and detailed notes for each wine.

The game-changer was implementing barcode and RFID systems. Each bottle gets tagged when it arrives, and our handheld scanners make inventory checks a breeze. It’s pretty cool watching new staff members’ faces light up when they realize they don’t have to count bottles by hand anymore! Plus, the accuracy is incredible – we went from a 95% to 99.9% accuracy rate overnight.

Stock rotation used to be my biggest headache. Trying to keep track of which wines needed to be moved or accessed first was like playing three-dimensional chess in the dark. Now, our system automatically flags wines that need attention, whether it’s for upcoming client pickup or just regular rotation, to prevent sediment buildup. It even generates optimized picking routes for our staff!

Client access has become super streamlined, too. Remember when clients had to call ahead and wait for someone to check their inventory physically? Those days are gone! Now, they can log into their secure portal, view their collection in real-time, and even schedule pickups or deliveries with a few clicks. The system automatically generates all the necessary paperwork and updates our inventory simultaneously.

Documentation is another area where technology has been a lifesaver. Every movement, every temperature reading, every client interaction – it’s all automatically logged and backed up. When a client once questioned whether their wine had been stored at the right temperature, I was able to pull up six months of environmental data in seconds. Talk about peace of mind!

Maintenance and Quality Control

Let me tell you about maintenance – it’s like being a wine guardian angel! I learned early on that preventive maintenance isn’t just about keeping equipment running; it’s about protecting millions of dollars worth of liquid investments.

Maintenance Schedule

We’ve developed a comprehensive maintenance schedule that covers everything from daily equipment checks to annual system overhauls. Temperature and humidity monitoring has become an obsession of mine (in a good way!). We check our digital monitoring systems multiple times daily, but I still insist on manual verification.

Physical Checks/Walk Through

Call me old-school, but there’s something reassuring about physically walking through the facility with a calibrated thermometer and hygrometer. It’s saved us from potential disasters more than once when a sensor was showing incorrect readings.

Cleaning Protocols

The cleaning protocols we’ve developed would make a hospital proud! Every surface gets regularly sanitized with wine-safe products, and we have strict procedures for dealing with any broken bottles or leaks. I once had a client ask why we were so meticulous about cleaning – then they saw how quickly mold can develop in the wrong conditions. Now they’re our biggest champions for cleanliness!

Emergency Response Drills

Emergency response planning isn’t just about having a plan – it’s about making sure everyone knows exactly what to do when seconds count. We run quarterly drills for different scenarios: power failures, cooling system malfunctions, security breaches, you name it. Sure, some staff thought I was being excessive at first, but after our first real emergency, everyone understood why we practiced so much.

Staff Training

Staff training is my secret weapon for quality control. Every team member goes through an intensive training program covering everything from wine handling to emergency procedures. We even bring in wine experts for educational sessions – because the more our staff knows about wine, the better they can protect it.

Commercial Wine Storage Regulations and Compliance

Navigating the world of wine storage regulations has been quite an adventure!

Compliance Calendar

When I first started, I had no idea how many different licenses and permits were required. These days, I maintain a detailed compliance calendar to track renewal dates for various licenses – everything from basic business permits to specialized wine storage certifications. Trust me, you don’t want to discover an expired permit during a surprise inspection!

Insurance

Insurance was another eye-opener. Standard business insurance just doesn’t cut it when you’re storing other people’s liquid investments. I learned to work with specialized insurers who understand the unique risks of wine storage. Our current policy covers everything from temperature control failures to earthquake damage – and yes, we actually had to use it once during a power outage that lasted several days.

Pro Tip: Please check the following specialized US Wine Insurers, InsureMyWine or HORTEN, for details and a quotation.

Safety Manual

Health and safety regulations? That’s a whole different ball game. We’re not just dealing with standard workplace safety here – we’re talking about specific requirements for alcohol storage, fire suppression systems designed for wine facilities, and specialized emergency protocols. I’ve developed a comprehensive safety manual that’s become something of a legend in the industry (several colleagues have asked to copy it!).

Certification

Getting certified was one of the best decisions I’ve made. Sure, it was a pain going through all the audits and inspections, but having those certifications gives clients peace of mind. Plus, it forced us to formalize our procedures and documentation in ways that have made our operation more efficient.

Documentation

Speaking of documentation – wow, is there a lot of it! Every bottle that comes through our doors has a paper trail that would impress a tax auditor. Client contracts, storage agreements, temperature logs, handling procedures – we keep digital and physical copies of everything. It might seem like overkill, but the one time a client questioned their wine’s provenance, having detailed documentation saved us from a potential legal nightmare.

Pro Tip for anyone getting into this business: Build relationships with local regulators and inspectors. I make it a point to be transparent and proactive about compliance, and it’s paid off countless times when we needed guidance on new regulations or had questions about requirements. Remember, these folks aren’t just enforcing rules – they’re helping ensure our industry maintains high standards for wine storage and handling.

FAQ – Commercial Wine Storage

- What is the ideal temperature for commercial wine storage? The ideal temperature range is 55-57°F (13-14°C), with minimal fluctuations.

- How much does commercial wine storage cost? Costs vary by location and capacity, typically ranging from $200-1000 per month for small to medium operations.

- What humidity level should be maintained in wine storage? Optimal humidity levels should be maintained between 60-70%.

- How often should temperature monitoring systems be checked? Daily monitoring is recommended, with automated systems providing continuous oversight.

- What type of lighting is best for commercial wine storage? LED lighting with motion sensors and UV protection is ideal.

- How much space is needed for a commercial wine storage facility? Space requirements depend on capacity, typically starting at 1,000 square feet for small operations.

- What security measures are essential for commercial wine storage? Access control systems, surveillance cameras, and alarm systems are crucial.

- How should wine bottles be organized in commercial storage? By client, wine type, and vintage using a clear labeling system.

- What insurance is needed for commercial wine storage? Comprehensive coverage including property, liability, and wine-specific insurance.

- How often should storage facilities be cleaned? Monthly deep cleaning with weekly maintenance cleaning.

- What backup systems are necessary? Backup power generators and secondary cooling systems are essential.

- How should wine deliveries be handled? Using established protocols for receiving, inspection, and documentation.

- What staff training is required? Training in wine handling, temperature control, and emergency procedures.

- How can inventory be tracked effectively? Using digital management systems with regular audits and updates.

- What certifications are recommended for commercial wine storage? Industry-specific certifications from recognized wine storage associations.

Conclusion

Successful commercial wine storage requires a careful balance of technical expertise, proper equipment, and systematic management.

By implementing the strategies and best practices outlined in this guide, you can create a reliable and efficient wine storage operation that meets the highest industry standards. Remember, investing in quality equipment and proper training will pay dividends in customer satisfaction and wine preservation.

Ready to elevate your commercial wine storage facility? Start implementing these recommendations today!

Good luck and Cheers!

For your reference, the latest articles by Didi Somm include:

- How To Pack A Wine Picnic Basket Like A Pro: Find Out Here

- Outdoor And Camping Wine Storage Hacks: Your Best Expert Guide

- Best Insulated Wine Tote Bags: Our Expert Tips for You

- Compact Wine Racks: Expert Advice On Best Use Of Space

- DIY Wine Carriers: 7 Creative Ideas That Surprise You

- Most Durable Wine Travel Accessories – Best Expert Guide For You

Important Notice: The information in this article is for general and public information purposes only. It solely reflects Didi Somm’s or his Staff’s opinion, and no responsibility can be assumed for errors or omissions in the service’s contents. For details, please check the Disclaimer at the bottom of the homepage.